The power grid’s capacity fluctuates, and sensors could reveal the actual capacity of the power lines in real-time – and it’s often significantly higher than presumed.

The lack of capacity in the power grid is limiting green industries, business development, the development of renewable energy production, and also limiting our ability to cut climate emissions. Furthermore, congestion in the grid has contributed to expensive electricity and significant differences in price between regions.

The situation is dire.

The demand for building more power grids is high, but building grids takes time, costs billions, and is often in conflict with nature and society. We need to build new power grids, but we can do more than that. Other measures can be quicker, cheaper, and involve less conflict. The first thing grid operators must do is implement and use innovative technologies that secure the efficiency of the grid we already have and the grid we’re building. We need to waste less.

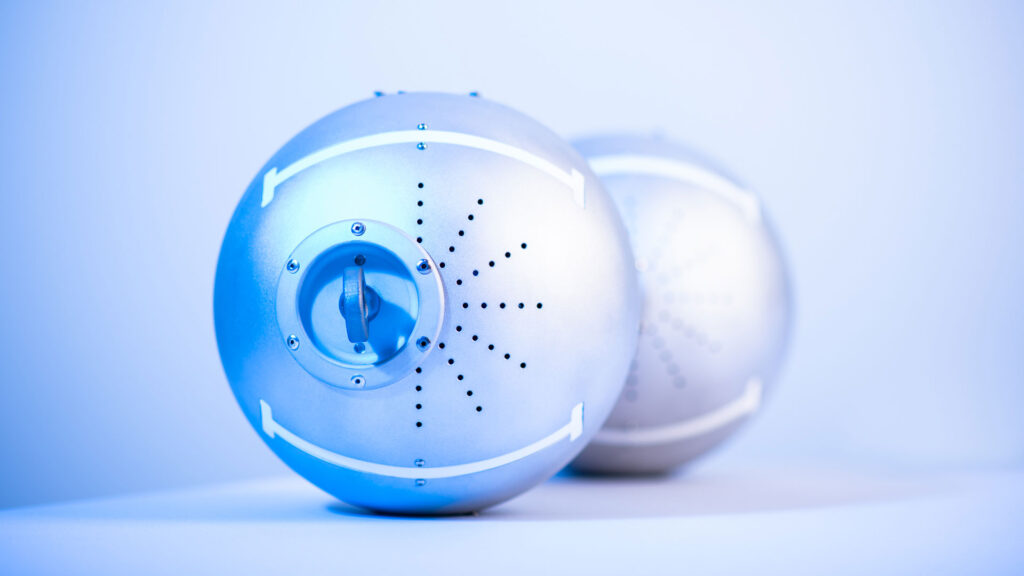

Power lines are traditionally assigned a conservative, static capacity limit by the company delivering them. However, in reality, a line’s actual capacity is dynamic and varies significantly based on weather and other factors. Today, sensors like the ones we produce at Heimdall Power inform grid operators of actual line capacity in real time, and the actual capacity is typically far higher than expected. Once we know a line’s actual capacity, we can use them more efficiently.

When we monitor actual line capacity over time, we gain insight we can use into everyday grid operations, the value of grid investments, and the potential of grid connections in enabling green industries and renewable energy production.

Studies show that power lines typically have actual capacity of about twenty-five percent more than grid operators are aware of. In other words, power lines are like a four-lane motorway where an entire lane is invisible to drivers. In some instances, it might be even more than one lane missing. Sensors that can inform grid operators as to their actual line capacities can be installed quickly, without adverse environmental impacts, and without long regulatory or licensing processes.

The new grid capacity is cheap because it’s old – the investment is already made. That fourth lane on the highway has waited for us long enough.

There is no requirement in today’s regulatory regimes for grid operators to know the exact line capacities on their grids. We believe such a requirement will come because today’s shortage of grid capacity causes higher electricity prices, more significant price differences, higher CO2 emissions, and slows the green shift for business and industry. In the future, we will make more dynamic use of our power lines. Anything less will be seen as an unacceptably wasteful use of resources.

In the future, we will also be able to make use of flexibility from electricity consumers. Consumer flexibility is another resource that is underused and wasted today. Batteries and energy storage systems will also contribute.

Efficient and dynamic use of the power grid’s capacity is a prerequisite for taking advantage of untapped flexibility in production, consumption, batteries, and other storage for our common good. When we are able to use the whole energy system more efficiently, we will also know better when and where to invest in our power grids. Risks of investing in stranded assets will be avoided, the speed of the green shift can increase, and the green shift can become more affordable for us all.

Now it’s up to the regulators to develop new regulations, and the grid companies to take responsibility and lead the way. The ball is in their court.