St. Olavs Gate 28 0166 Oslo, Norway

214 W. Tremont Ave, Suite 301

Charlotte, NC 28203, USA

Ambient Adjusted Rating (AAR) is a technology that has been developed to improve the transmission capacity of overhead power lines. It takes into account the ambient temperatures, and potentially also other environmental factors, and combines it with relevant historical data. This article will explain how AAR works, its benefits and challenges, and how it differs from other comparable technologies such as Dynamic Line Rating (DLR).

Ambient Adjusted Rating (AAR) technology works by utilizing existing environmental data. This is combined with high-quality weather forecasts, to adjust and rate the performance and condition of overhead lines. The process typically involves collecting data on ambient temperature, both in the past and for the future, while data on parameters like humidity, lighting levels, wind speed and wind direction typically are static assumptions.

The ambient data is then used as input parameters in an algorithm that will provide a transmission rating of the overhead lines in the given areas, based on the forecasted weather conditions. The rating algorithm takes into account the predetermined correlations between the collected ambient data and the performance characteristics of the overhead lines in question. By analyzing these correlations, the algorithm determines the adjustments needed to reflect the actual performance within the given environmental context. Ambient Adjusted Rating can typically be forecasted for up to ten days, where the uncertainty will increase the longer into the future you get.

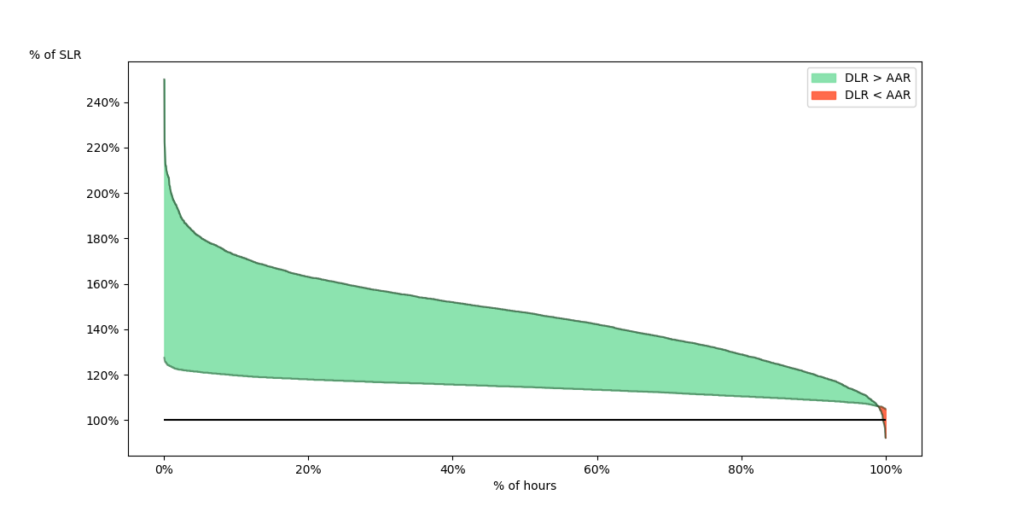

The key advantage of Ambient Adjusted Rating is its cost-effectiveness and ease of implementation. Unlike traditional overhead line rating systems, that require physical sensor units, AAR utilizes existing environmental data and weather forecasts to provide an adjusted rating. This means that such systems can be up and running in mere minutes. Compared to a baseline scenario with no grid monitoring, AAR offers better assessment of the ambient conditions around an overhead line. At Heimdall Power, we typically observe an average increase in available transmission capacity of 13% when using Ambient Adjusted Rating. The graph below shows how AAR ratings can compare to DLR and Static Line Rating (SLR) over time.

Ambient Adjusted Rating also comes with some challenges. First and foremost, the reliance on assumptions rather than actual real-time sensor data is the key challenge associated with the AAR technology. While it can provide a reasonable estimation of performance within the given environmental context, AAR may not account for sudden or unforeseen changes in local conditions. Specific environmental factors might not be captured by the ambient data, leading to an AAR rating that may not accurately reflect the true capability of the line(s) in question. This could in worst-case scenarios lead to overloads or black-outs in the grid. Such situations could occur in the orange area in the graph below. Hence, grid operators will often instrument their critical lines with physical sensor units, obtaining increased operational safety and observability.

The graph above shows aggregated data from some of Heimdall Power’s installations with DLR and AAR. The green area indicates where DLR provides additional available capacity compared to AAR, while the small orange area indicates how often AAR will overestimate the line’s capacity. The Static Line Rating (SLR) option is indicated by the black line, constant at 100%.

Ambient Adjusted Rating (AAR) rates the transmission capacity of overhead lines based on ambient temperature, and potentially additional factors. Dynamic Line Rating (DLR) uses real-time sensor data to identify the line’s actual capacity in any given moment. Hence, their source of input data is the biggest difference between Ambient Adjusted Rating and Dynamic Line Rating, where DLR has the superior accuracy. On the other hand, AAR implementation is normally less expensive and time consuming than what is the case for DLR.

Combining the best of both worlds, instrumenting the whole power grid with a combination of AAR and DLR, based on criticality of the lines, looks like the way forward for the transmission industry. You can read more about Dynamic Line Rating in this article.

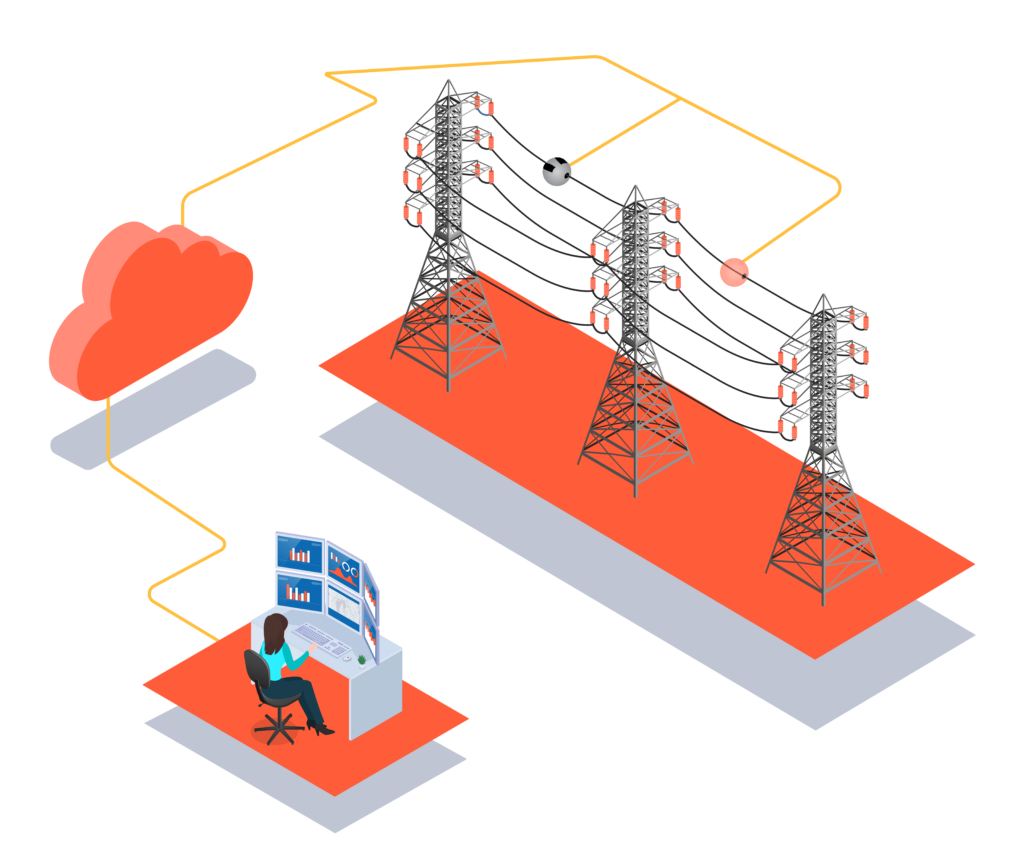

The illustration on the right shows how we do DLR and enhanced AAR at Heimdall Power, utilizing our Physical Neuron & Virtual Neuron sensors.

To make better use of the existing infrastructure, maintaining grid reliability and keep customer rates as low as possible, the Federal Energy Regulatory Commission in the U.S. has approved FERC Order 881. By the requirements of this order, all transmission lines in the U.S. will need to have a certain amount of grid monitoring by July 2025. Ambient Adjusted Rating is one of the ways grid companies can meet the requirements of FERC Order 881.

Heimdall Power provides a seamless system for setting up AAR, thereby meeting the FERC Order 881, by using our self-developed Virtual Neurons. AAR can be configured to be set up with default CIGRE or IEEE recommended weather assumptions or customized ones, based on the clients needs and the specifics of each power line. High-quality weather data is fetched every hour, and used to calculate AAR for every relevant line segment. Results are aggregated to provide a single valid and safe to use AAR value for real-time operations and up to 10 days of forecasts.

In summary, Ambient Adjusted Rating can be a useful tool for utilities to improve the transmission capacity and monitoring of their overhead lines. When used right, the technology provides an easy gateway to grid monitoring for utilities that aim to utilize their grid better. By using AAR technology, utilities can normally increase the transmission capacity of their lines without compromising safety or reliability. This provides a win-win solution for utilities, regulators, and consumers alike.

Would you like to know even more about Ambient Adjusted Rating? Heimdall Power is a world-leader on overhead line rating technologies and competency, and we are always ready to help you increase your knowledge, grid capacity – or both. Contact us, or use the buttons below today to get started!

Heimdall Power´s vision is to optimize power grids globally. Since 2016 our innovative technology has optimized grid utilization with state-of-the-art software and unique hardware technology. We continue to innovate and improve, creating value for customers, shareholders and society.

St. Olavs Gate 28 0166 Oslo, Norway

214 W. Tremont Ave, Suite 301

Charlotte, NC 28203, USA

Heimdall Power´s vision is to optimize power grids globally. Since 2016 our innovative technology has optimized grid utilization with state-of-the-art software and unique hardware technology. We continue to innovate and improve, creating value for customers, shareholders and society. Our smart grid technology allows you to be the guardian of the grid.

St. Olavs Gate 28

0166 Oslo, Norway

214 W. Tremont Ave, Suite 301

Charlotte, NC 28203, USA

We expect our vendor partners to maintain the highest standards of business ethics, integrity and respect for human rights and to become familiar with and comply with our policies as outlined in our Partner Guide. We also expect vendor partners to operate their businesses in compliance with all applicable laws and to maintain lawful environmental, health and safety practices that meet or exceed all applicable laws and standards, as outlined in our Position on Human Trafficking and Slavery.

The Supplier is to hold and maintain at all times the Heimdall Code of Conduct addressing human rights, worker rights, the environment and corruption.

The Supplier must acknowledge HP’s Code of Conduct in all new contractual arrangements. The Supplier must do this by signing the HP Compliance Letter (exhibit).

The Supplier is obligated to communicate the contents of Compliance Letter (Exhibit) to related entities and subcontractors who support the Supplier in supplying goods, works or services on behalf of HP. This will ensure that subcontractors conduct their business in accordance with the Code of Conduct.

If requested by HP, the Supplier must provide evidence and confirmation of its compliance with the Compliance Letter (Exhibit), including by providing documents and records in support of its compliance.